LEM Technology

Introduction to LEM Technology

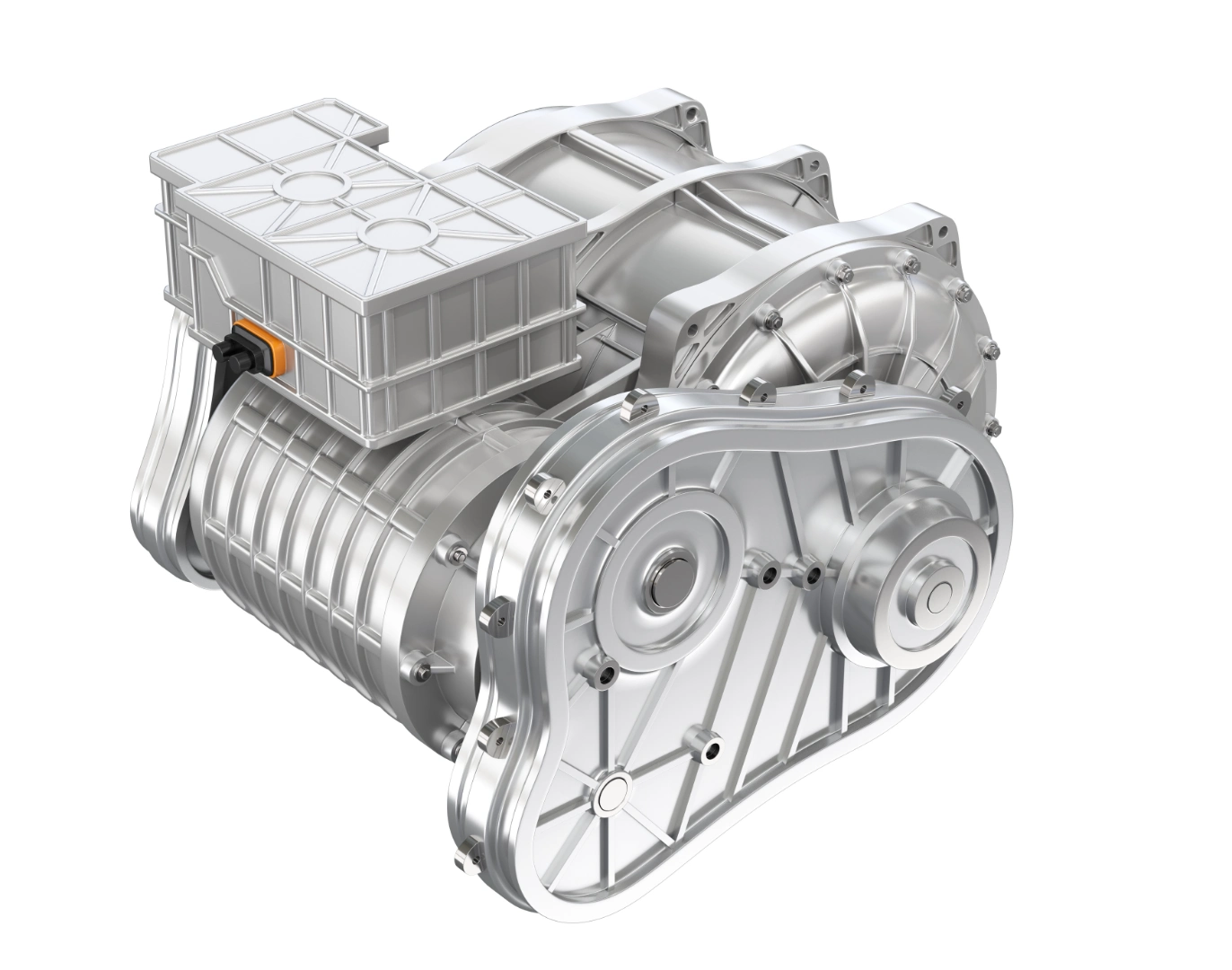

Solyem’s static sealing technology also known as LEM technology for gasket, has been invented, patented and produced since the year 2000, and is present within a multitude of combustion engine systems and developed to answer the newest technologies being designed within the E-mobility movement.

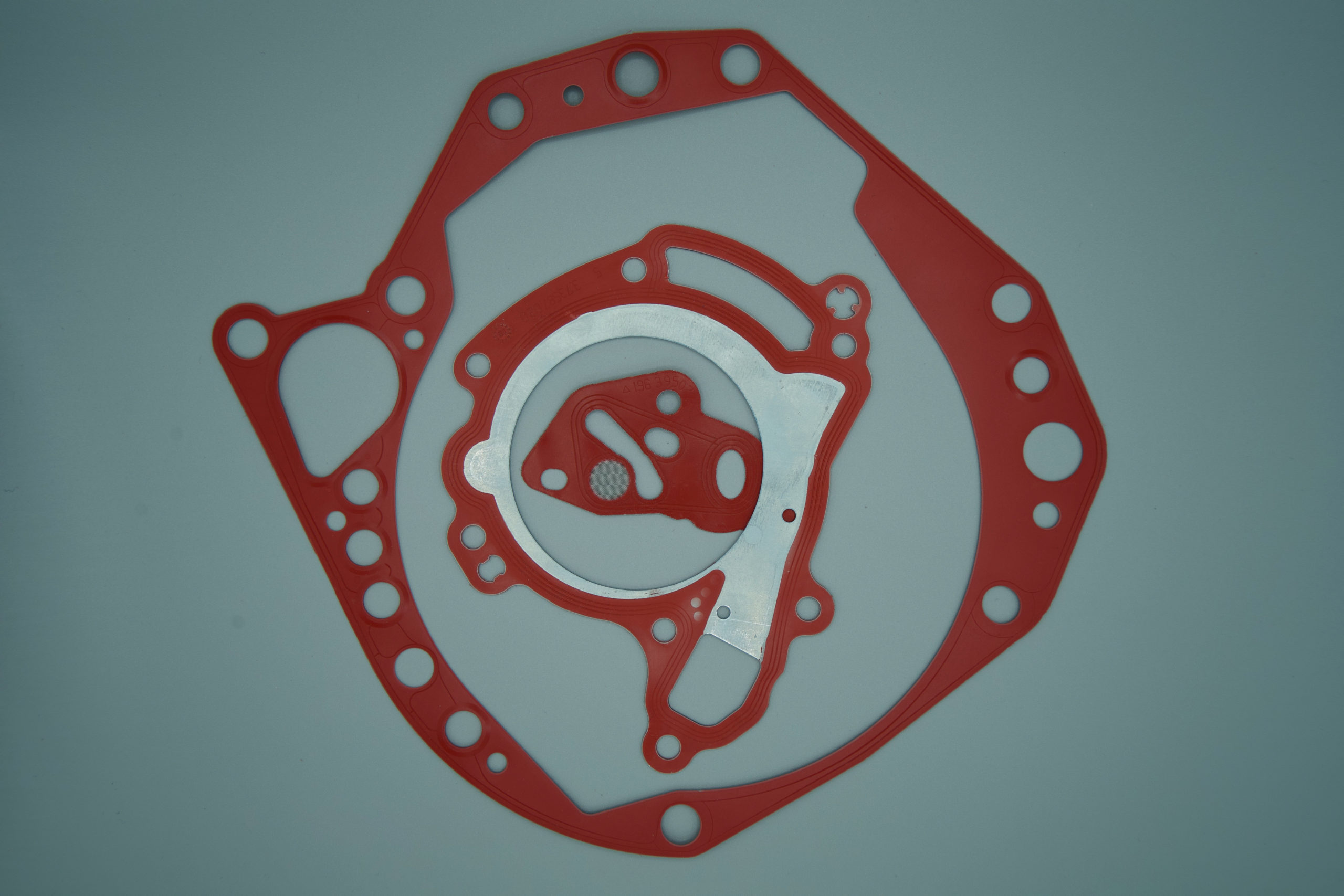

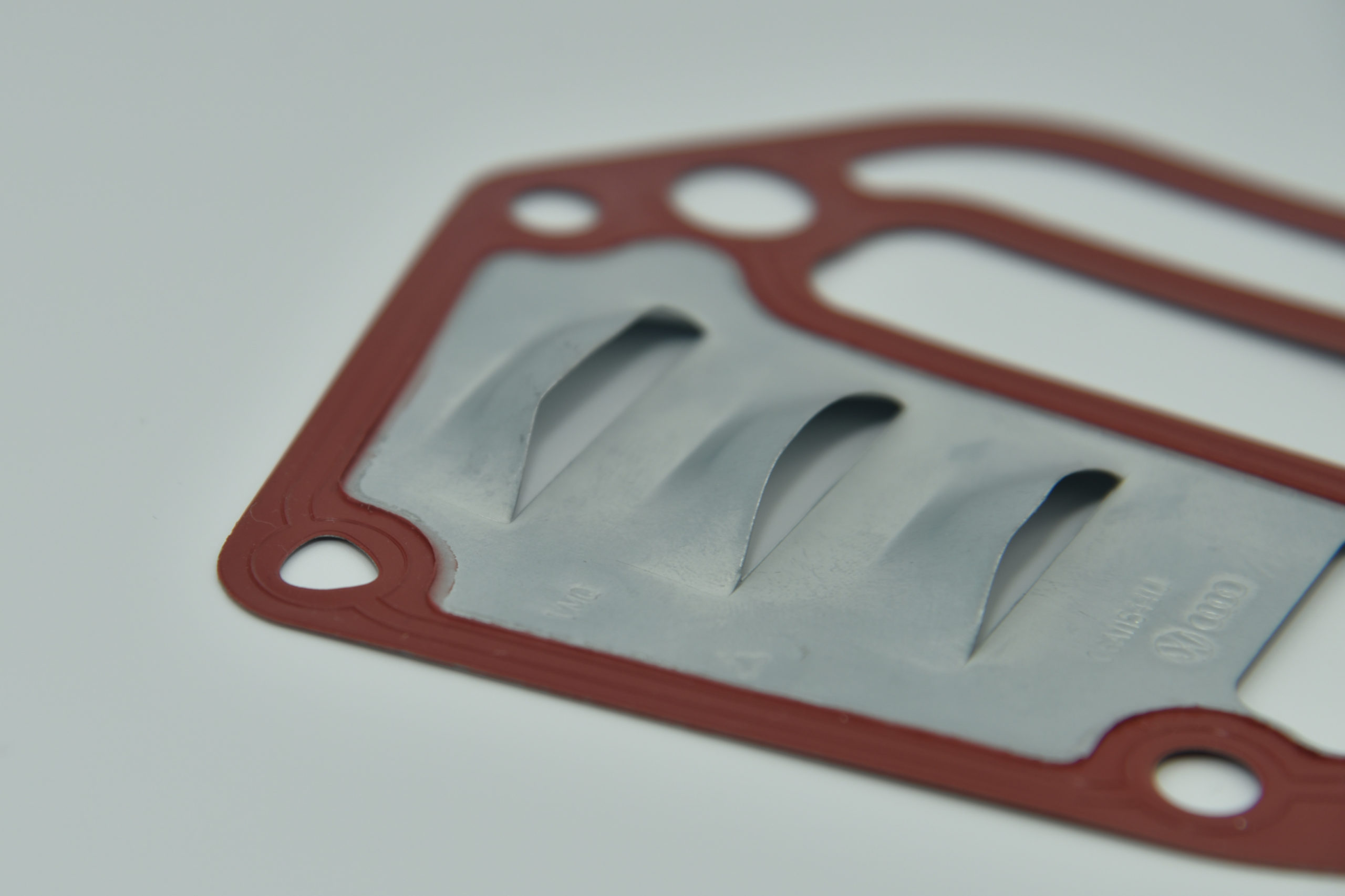

Several silicone beads or barriers molded on the top of the gasket along with our topography pattern ensure the seal in-between the two parts to be sealed. Our LEM technology enables excellent sealing function and design simplification of our customers’ parts. In addition, we can supplement our LEM gaskets with other useful functions.

During 100 years of gasket development and more than 20 years of our LEM technology experience, we have developed best practice and a specific design and development process, which we use to ensure sealing results.

Benefits of LEM technology

- Compensates variable flange distortions and flatness defects => wide range of application and improved product reliability

- Reduces the amount of bolts used for your assembly => weight and cost reductions

- Reduces wall thickness on housing systems => weight and cost reductions

- Permits high roughness of your housings and covers => machining cost reductions

- Compatible with automatic assembly lines => assembly cost and cycle time reductions

- Our gasket can be pre-assembled on one of your part and then conveyed to other production stages until final assembly => assembly process ease

- Bespoke LEM designs to your distinctive needs

Functions of LEM

Benefits of our LEM gasket technology lies in the optimization of the sealing’s properties and also in the possibility to add other essential functions to our gaskets. For example, we have solved some of our Customers’ issues by designing our gasket with electrical conductivity function.

We are also able to design and produce our gasket integrated to the cover, so that our Customer can manage one part instead of two and optimise its production.

For another project, we offered a gasket with an integrated filtering function of the oil passing through our Customer’s system. This double function is definitely a high added value for our Customer. Moreover, we ensure outstanding quality, figures below speak for themselves.

Quality excellence of LEM Technology

Over

20

Years

of production

Over

200

Million

LEM gaskets produced

0

field claim

in the history of the LEM technology

5

PPM

over the last 10 years

Contact

34 chemin Pierre Blanche

69800 SAINT-PRIEST

France

Switchboard: +33 4 72 23 25 25

Human Resources: +33 4 72 23 25 01

Sales: +33 4 72 23 24 57