Here is what makes LEM so unique

Products

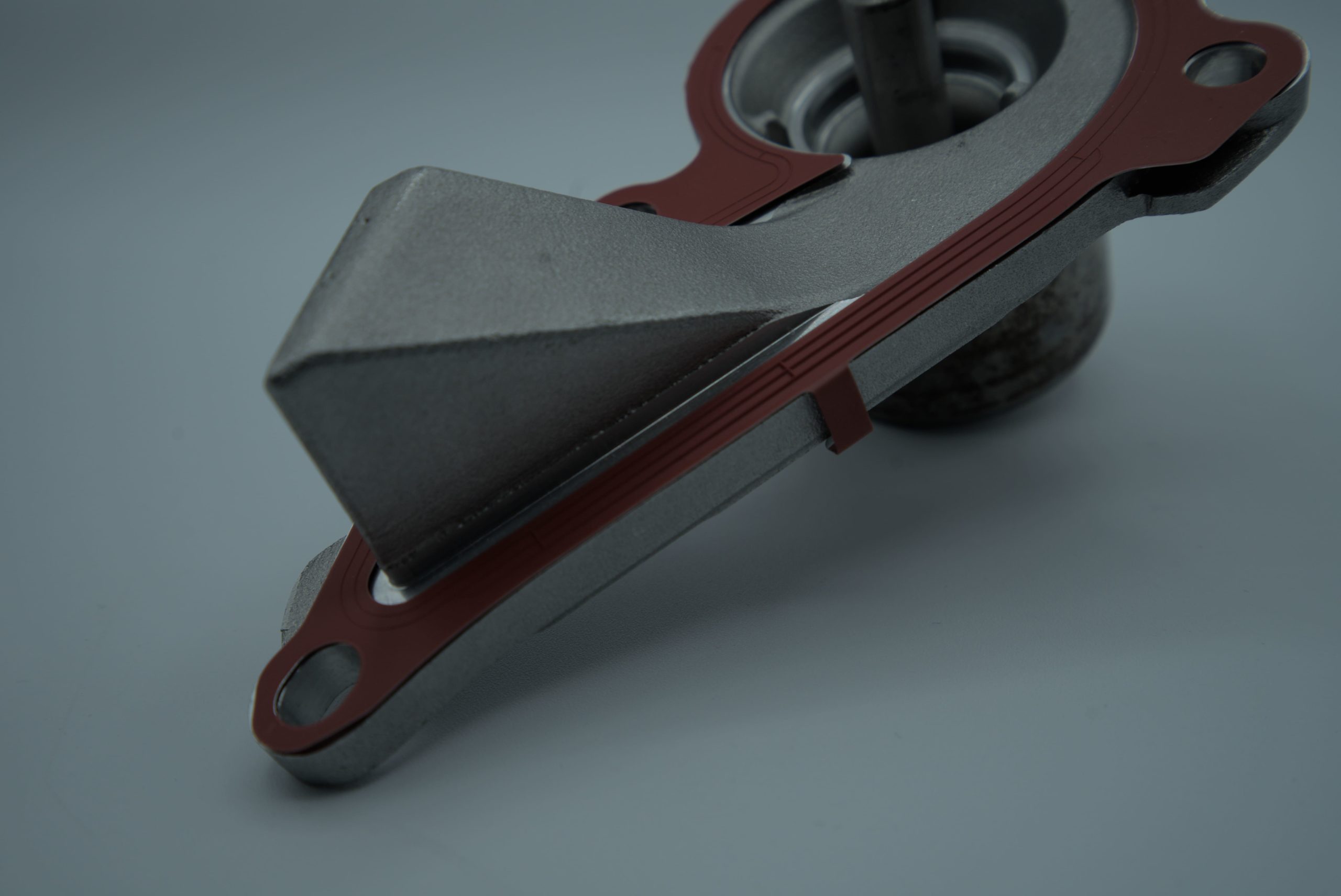

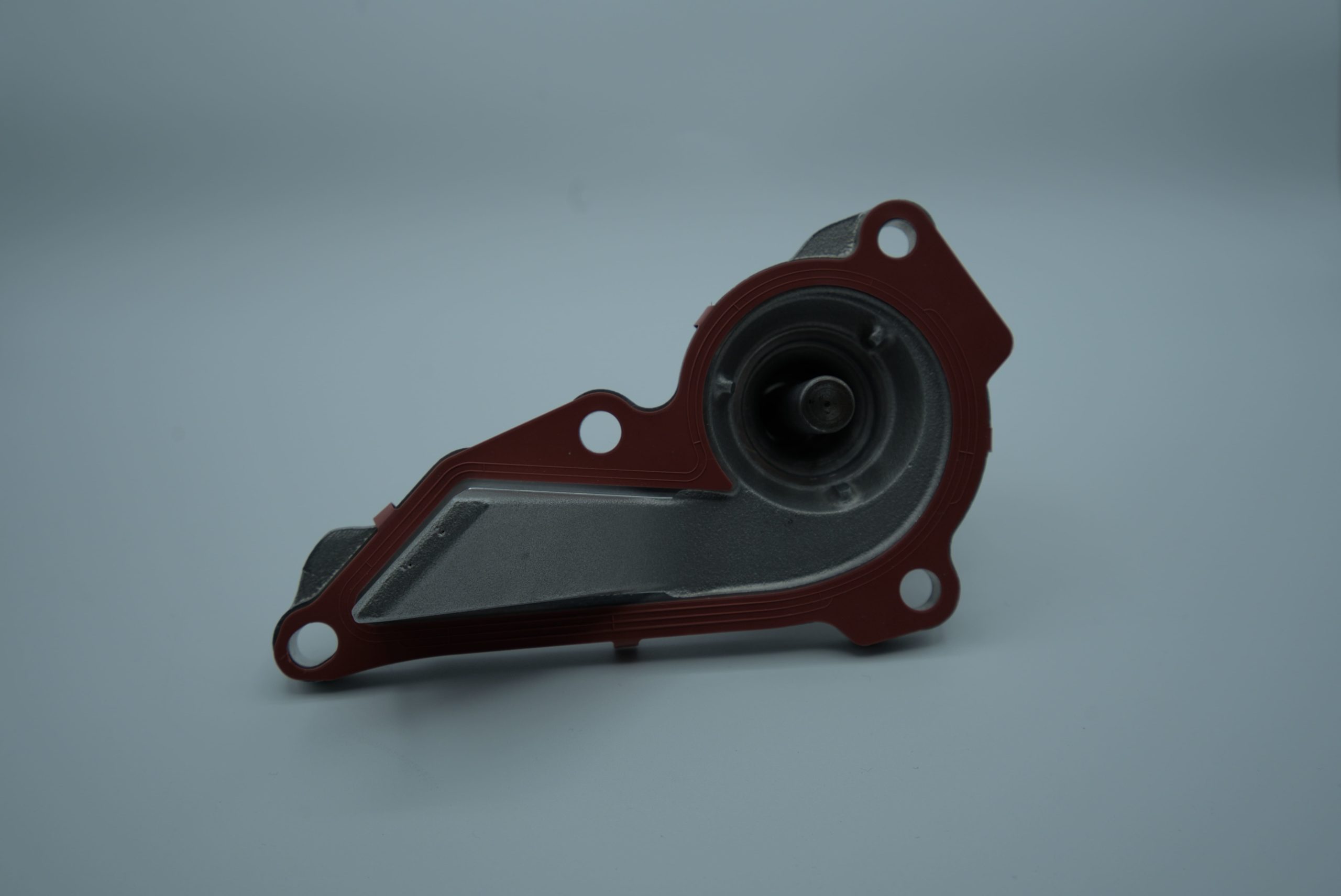

Gaskets & Sealing

Pumps

Hydrogen fuel cell gasket

Thermal engine

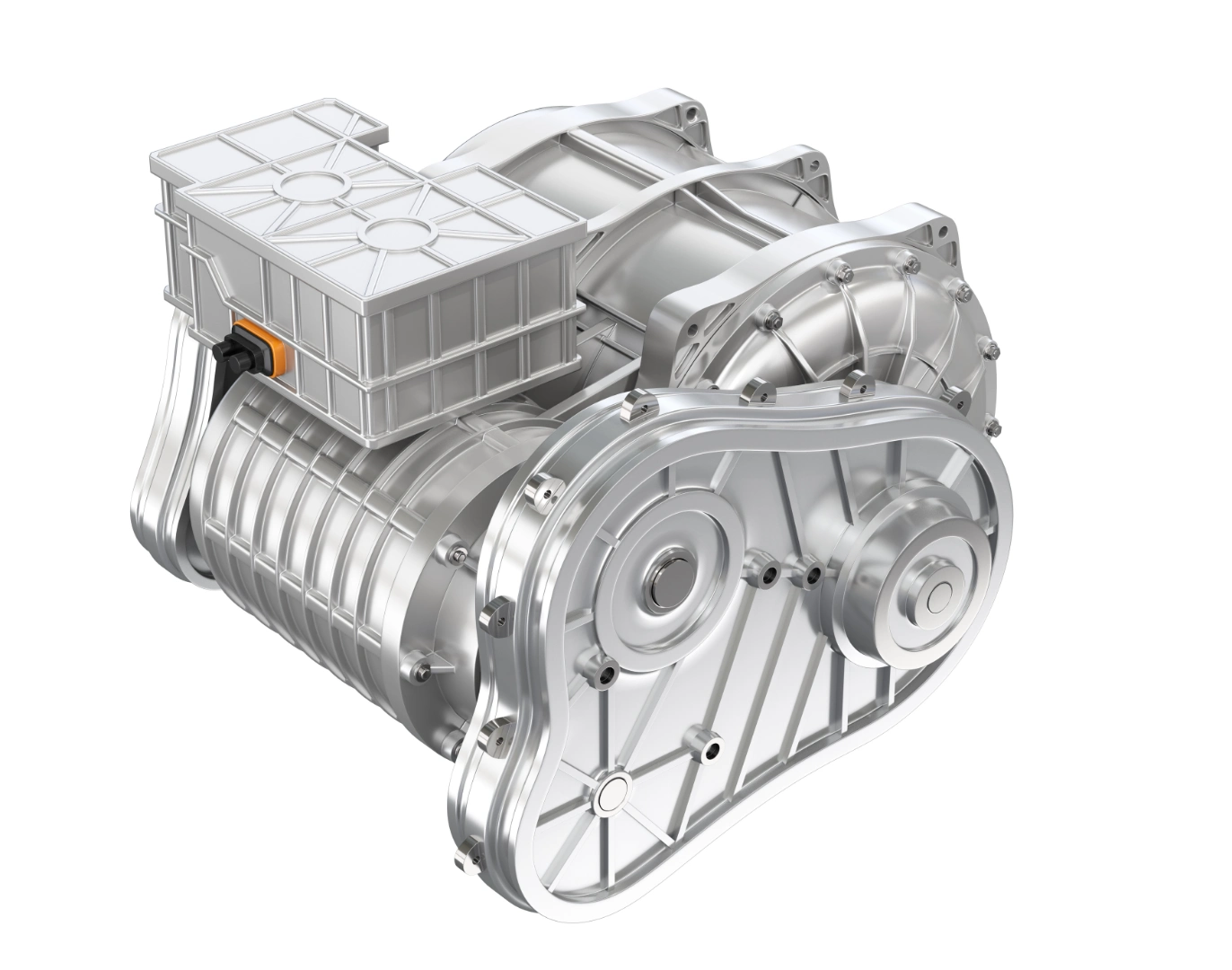

Electrical motor

E-bike

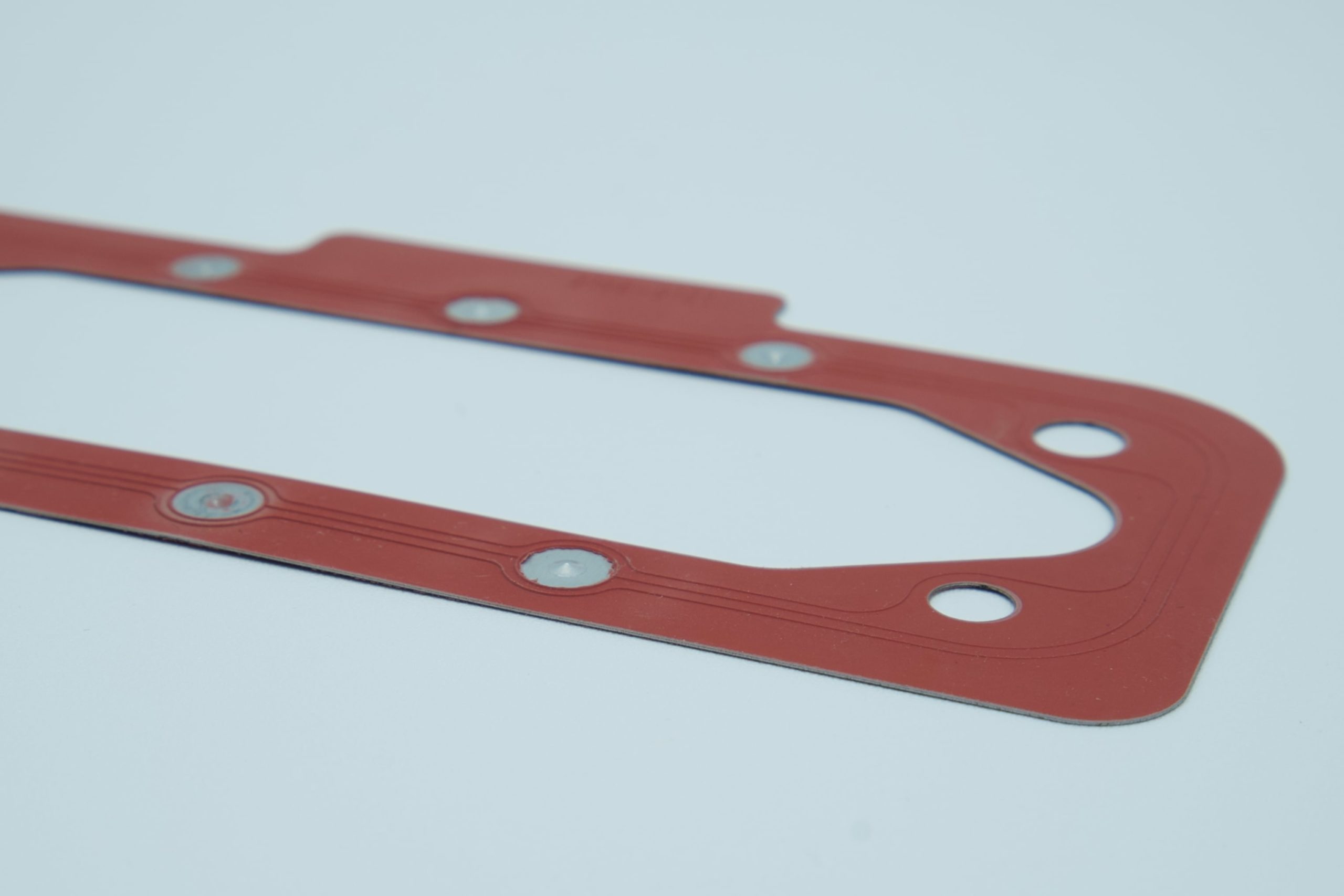

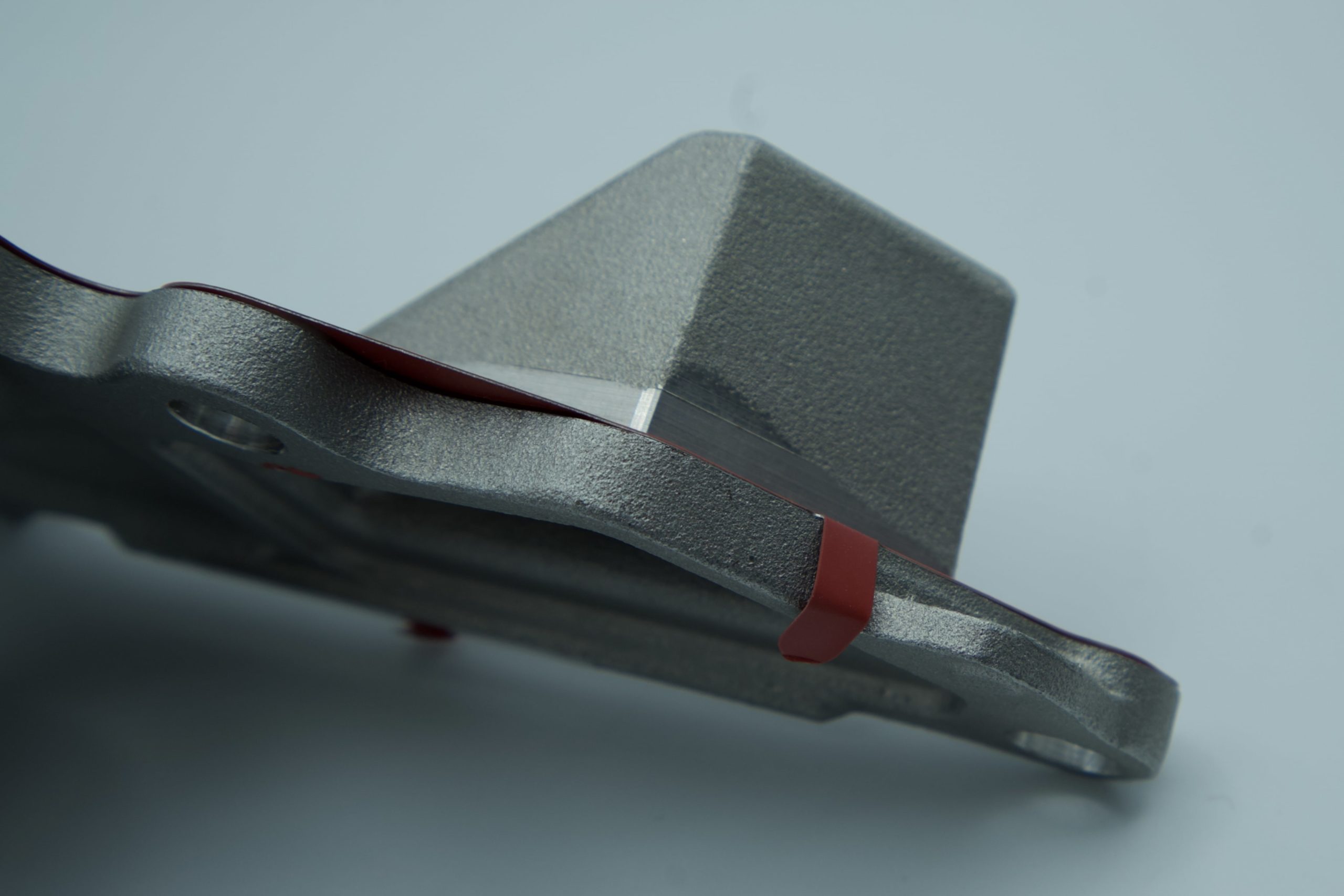

Our LEM gaskets are made of a carrier in zinc-coated (galvanised) steel, stainless steel or aluminium, overmolded with a liquid elastomer. The thickness of the carrier varies from 0,1mm to 1,5mm, according to your needs.

The elastomer shape is designed on both sides of the gasket with several sealing beads parallel one to another. The height of the sealing beads is topographically adapted to the deformation of your housings and flanges. Our LEM technology is adapted to the customer’s requirements and the gasket’s shapes and characteristics are customised accordingly to the parts, guaranteeing an efficient sealing on all types of static problematics.

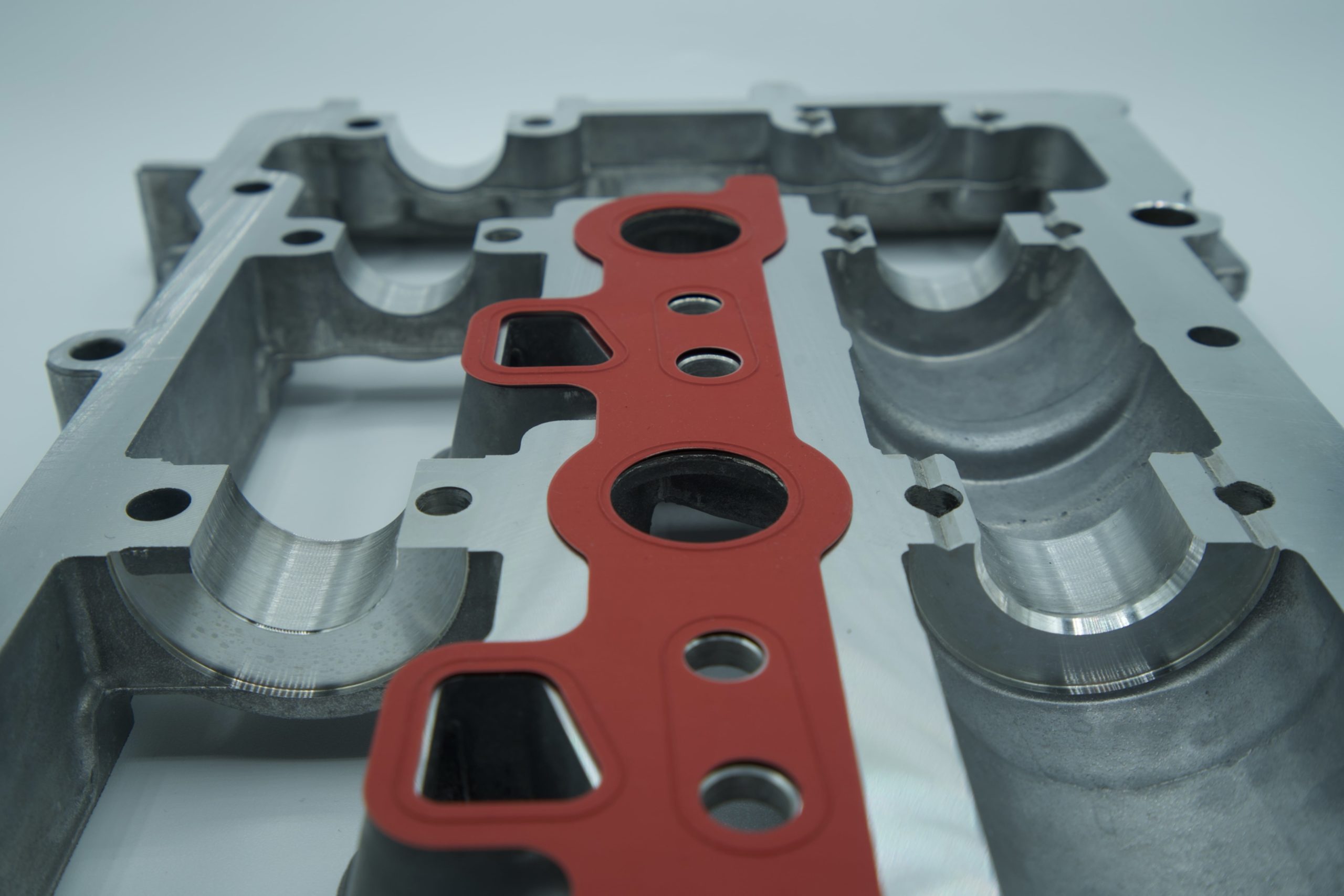

Conductivity throughout LEM gaskets

Hydrogen fuel cell gasket

Electrical motor

E-bike

The LEM gasket technology enables electrical conductivity on demand by designing embossments in the metal carrier. It allows a metal contact between gasket and housing parts.

Due to this electrical conductivity, the LEM gasket avoids electromagnetic effects in the assembly of parts.

LEM design for high pressure fluid

Pumps

Hydrogen fuel cell gasket

Thermal engine

Our LEM gasket solutions are engineered to optimise the sealing performance with different pressures.

The surface molded sealing beads can be used for low-pressure fluids<10 bars. Edge molded elastomer is used for high pressure fluids up to 30 bars.

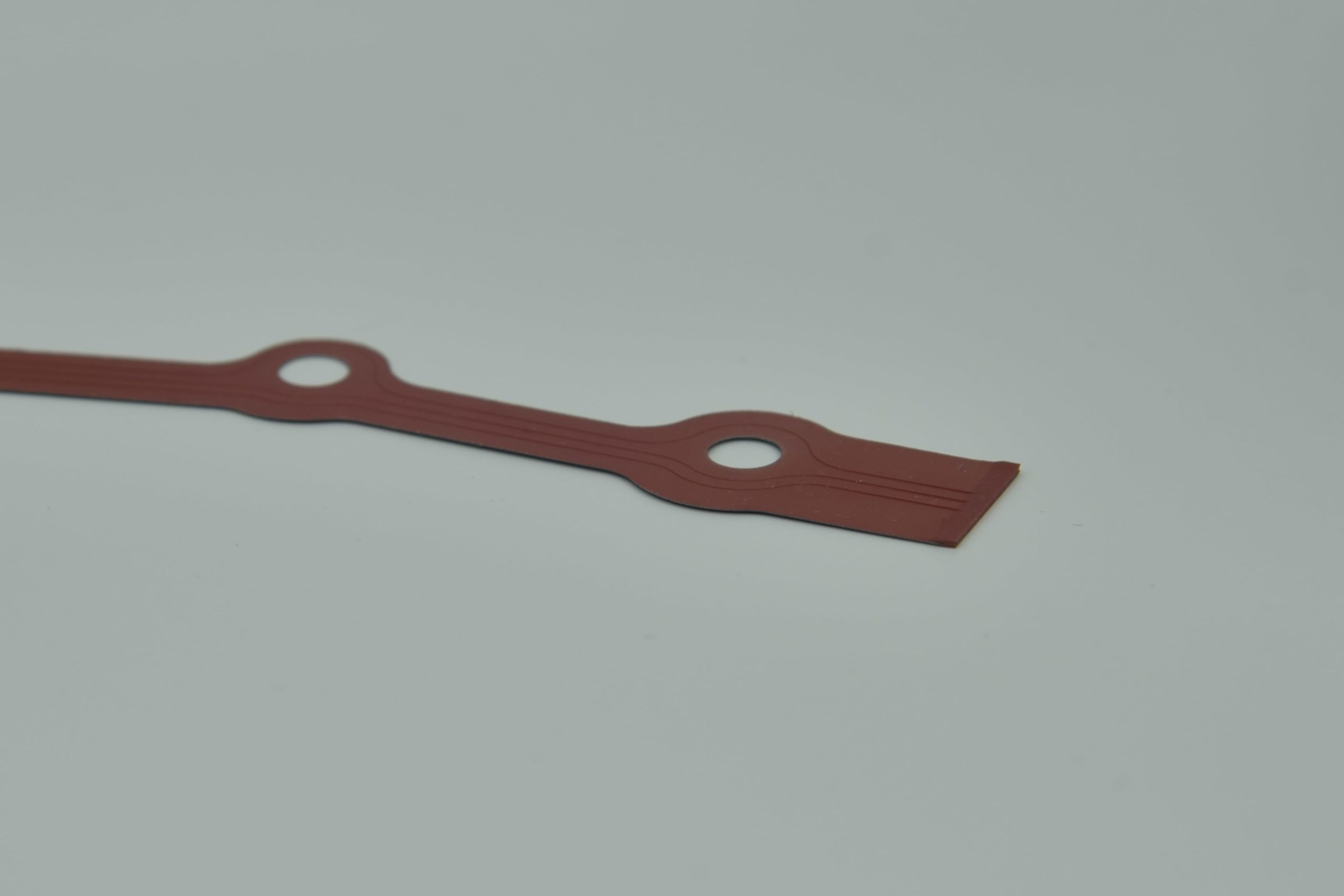

LEM T-junction

Hydrogen fuel cell gasket

Thermal engine

Electrical motor

By designing what we call a T-junction in our LEM gaskets, we are able to seal a third surface.

The T-junction is a location in the gasket where there is no carrier. By compressing the gasket between the two main flanges, the free elastomer will flow to the third surface to seal it together.

Filtration by LEM

Pumps

Hydrogen fuel cell gasket

Thermal engine

LEM gaskets are tailor made, so that they can fit all your applications perfectly.

Other functionalities can be added to the sealing function like filtration.

A filter can replace the carrier of the gasket so that one part can have several functions. It helps you optimise your assembly process in time and in cost.

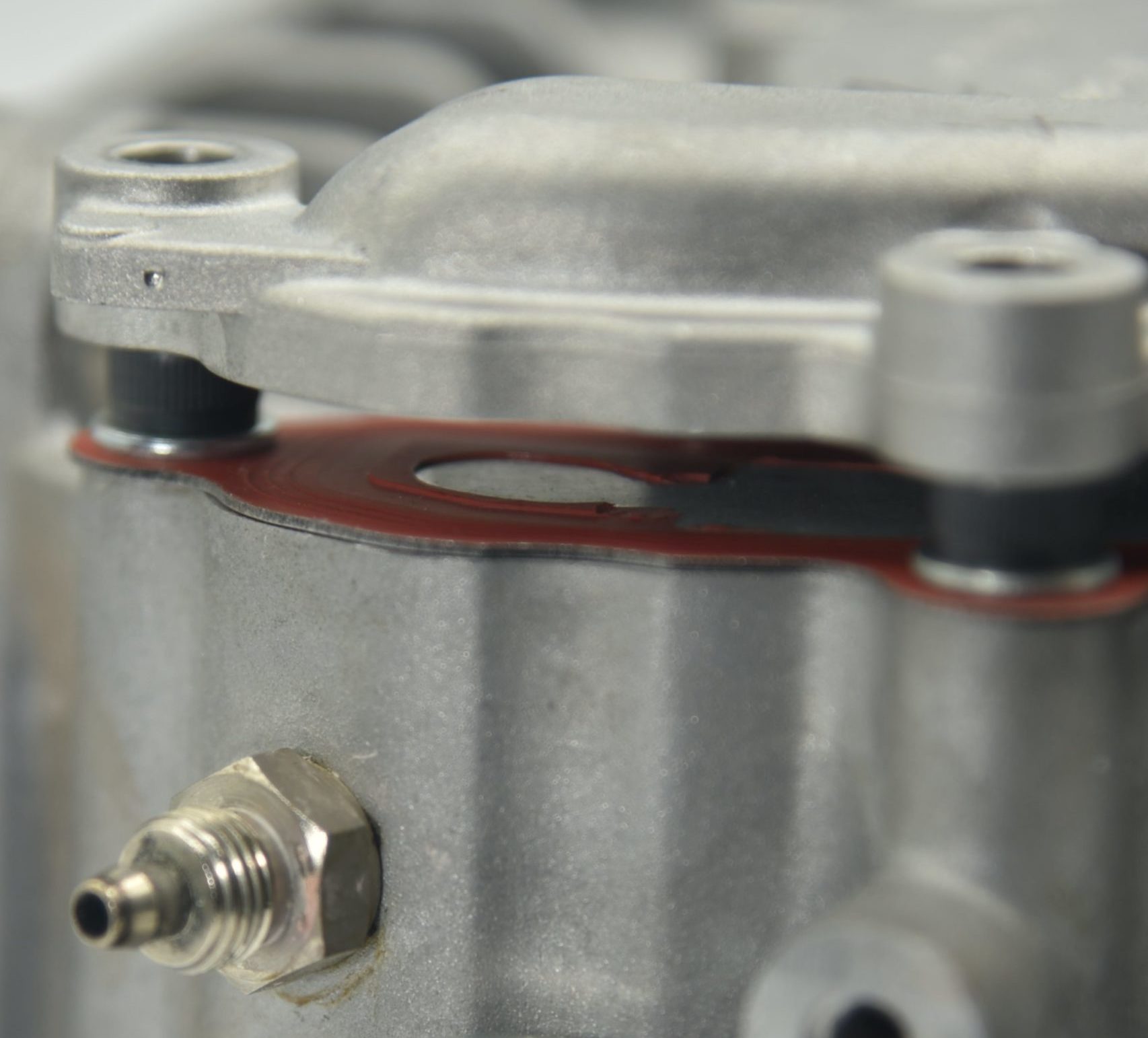

Cover

Our LEM technology can be used to create a self-sealing cover.

This function ensures both a seal and the closing of a housing, thus optimising your assembly process by having only one part instead of two.

Processes

Easy assembly: manual or robot

Our LEM technology enables an easy and quick assembly of the gasket on your housing parts thanks to its natural rigidity.

This assembly can be done manually or with an automatic device, therefore optimising your assembly process.

Pre assembly

3 specific structures can be applied to our LEM technology to allow the preassembly of the LEM gasket on your housing parts :

- Gasket tabs can be folded to the part

- Gasket can be pressed on locating pins

- Triangle holes can be designed to hold the screws in place

Contact

34 chemin Pierre Blanche

69800 SAINT-PRIEST

France

Switchboard: +33 4 72 23 25 25

Human Resources: +33 4 72 23 25 01

Sales: +33 4 72 23 24 57